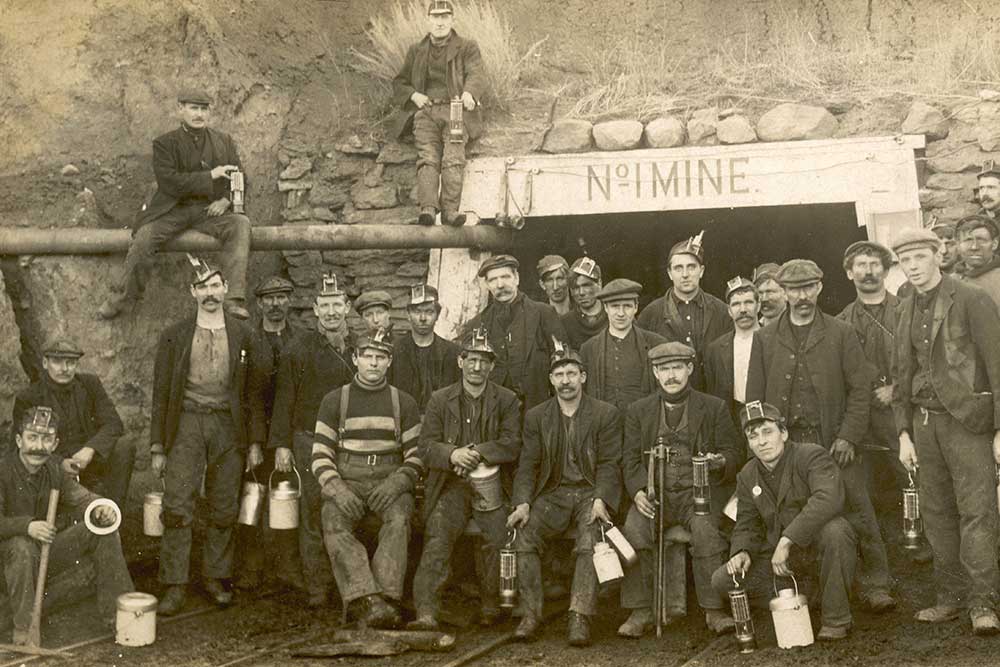

The History of Miner Lamps

Safety Lamps Past and Present

In the early days of mining in the United Kingdom, bunches of resinous materials were used for lighting the outcrop workings.

In the early days of Coal Mining there was little, if any air circulation in the mines so the dangers from explosions, due to firedamp, were high due to the fact that marsh gas requires a certain proportion of air before it becomes explosive.

Earthen oil lamps were used at first, until the fear of explosions led to the use of dried fish scales from which a faint phosphorescence light was emitted. It is obvious, however, that such a method must have led to mining work being carried out without almost any light.

Tallow Candles

Tallow candles were subsequently used both for lighting and for searching out gas. A small candle was carried in a wet lump of clay – the flame reduced in size by placing clay at its lower extremity near the exposed portion of the wick according to Caleb Pamely’s “Colliery Managers’ Handbook”.

The candle was raised, gradually with one hand of the observer held palm outwards towards the light to shield it entirely from view except the very tip of the flame. As it was raised an appearance of ‘top’ or ‘cap’ of blue flame above the candle flame indicated the presence of gas in the air.

As soon as this appeared the candle would be gently lowered, the searcher would withdraw with as little disturbance as possible. Before commencing to do this, the man would retire to a distance, away from the outgoing currents, his candle left out of the passing firedamp.

The ‘Fireman’

Another method of eliminating a small quantity of gas was to set fire to it. A special operator or ‘fireman’ with tremendous nerve did this at night.

Protective attire might consist of wool, or leather, well damped, with the man’s face and head protected by a mask or hood. Using a long stick with a lighted candle attached to the end, he would crawl the last few yards toward the explosive gas, his head and body close to the floor. Immediately afterwards he would stand upright (or as much as the space would allow) to avoid the carbonic acid gas left by the explosion.

The name ‘fireman’ has been retained to the present day for the man who searches for gas. In some countries he was called the ‘penitent’, on account of the resemblance of his dress to certain religious orders in the Roman Catholic Church. In many instances, in spite of all precautions, the fireman did not survive the explosion.

The Steel Mill

The first apparatus for producing light was Spedding’s ‘Steel Mill’, patented in 1760. It consisted of a spur wheel and steel disc placed in a small steel frame, at the end of which the operator held a piece of flint.

The continuous succession of sparks emitted by the rotation of the disc against the flint gave warning of danger by indicating the presence of firedamp. The faith in the ‘Mill’ was immediately shattered by a serious explosion at the Wallsend Colliery in 1785.

Race for a Solution

The first attempt to use a lamp was made by Humboldt in 1798, but it would not burn in the presence of impure air and was therefore not practical for use in a coal mine.

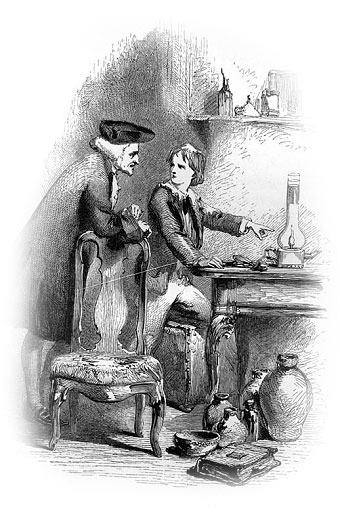

The first person to demonstrate that a steady light could be employed in coal mines without the danger of external explosion, was Dr. William Reid Clanny, of Sunderland. On May 20th,1813, he announced his discovery at a meeting at the Royal Society of Arts in London, when he presented the Society with the first miner’s ‘Safety Lamp’.

The first oil-burning, safety lamp, utilizing gauze cylinders, was invented by Sir Humphrey Davy. He never claimed to be the inventor of the Miners’ Safety Lamp. In fact, on November 9th, 1815, when announcing to the Royal Society his discoveries on the nature and properties of firedamp, he gave a description of Clanny’s lamp, which he had seen in use at a northern colliery.

The first Davy Lamp was tried at Hebburn Colliery, January lst, 1816. Strictly speaking, the ‘Davy’ is not a lamp but a scientific instrument for detecting the presence of firedamp. All lamps of the present day embrace the principles of the Clanny and the Davy.

History Continued

The first lamp made for George Stephenson was tried at Killingworth Colliery, Northumberland, October 21st, 1815. It was a comparative failure.

Stephenson’s third lamp was more successful, and on December 21st, 1815, he exhibited it to a number of colliery owners and officials at the Literary and Philosophical Institute, Newcastle upon Tyne. Gratification at this success was checked when he learned that Davy had also entered the field. Davy was the competitor he feared. Stephenson did not hesitate to adopt Davy’s idea of the gauze cylinder nor did he regard it as piracy. In his pamphlet entitled ‘A Description of the Safety Lamp invented by George Stephenson’, published in 1817, he states that he regarded the substitution of a ‘gauze cylinder for a perforated case’ as ‘merely a variation in construction’. Nor was he inclined to give Davy much credit for his discovery, declaring that ‘the person who first constructed the perforated tin can lanthron in common use may, with great justice, claim the merit of having surrounded flame with a substance less liable to injury than glass’, which he subsequently produced as the ‘Improved Stephenson’, or ‘Geordie’.

This lamp was practically a Davy Lamp with a glass cylinder inside the gauze. Indeed, the Royal Commissioners, in their report dated March 15th, 1896, stated, ‘if the glass breaks the Stephenson Lamp becomes a Davy’. The ‘Davy’ and ‘Geordie’ have long since been relegated to the list of obsolete lamps.

Stephenson, however, frankly admitted his indebtedness to Dr. Clanny. In his pamphlet already referred to, he states, ‘There can be no question upon the merit of the discovery, as there is no doubt that Dr. Clanny directed his talents to the subject and had constructed his original lamp, before I had reduced my ideas into practice.’

Continuing his experiments, and following up Davy’s discoveries, Dr. Clanny, in conjunction with the late John Mills, to whom he granted the sole manufacturing rights, eventually produced his ‘lmproved Clanny Lamp’. He adopted gauze cylinders but made them 2 inches shorter than Davy’s. He used a circular glass for surrounding the flame, but made it 3 inches shorter than Stephenson’s.

Improved scientific methods of ventilation greatly increased the velocity of air currents in coal mines. Neither the Davy, Clanny, nor Stephenson lamps proved of practical in currents exceeding 400 to 800 feet per minute. In some cases their employment provided an element of danger, for among miners and officials there prevailed considerable ignorance on the question of noxious gas and the principles of the safety lamp. Thus it happened that for several years after the introduction of safety lamps explosions in coal mines were more frequent and more disastrous than they had ever been before. In Belgium and France, where the mines are deep and fiery, Governments made the use of safety lamps a question for the state, and they appointed Commissioners to decide the merits of the various lamps then in use.

Both Governments decided in favor of the Mueseler, and the use of other kinds was prohibited. This, however, did not prevent the recurrence of appalling disasters, and the Mueseler, it was found, was in certain circumstances, a more dangerous lamp than some of those it superseded. The Mueseler is a form of the Clanny with a chimney inside the gauze.

In 1884, the British Government appointed a Royal Commission, ‘To inquire into accidents in mines, and the possible means of preventing their recurrence or limiting their disastrous consequences’. In the course of their investigation, they found that ‘at least 60 per cent of the average of the deaths resulting from accidents in connection with coal mines were caused by explosions of firedamp and from falls from the roof and sides’. It was clearly proved that, to a large extent, these disasters were due to the inefficiency, or to the defective construction of safety lamps. The committee, therefore, ‘considered it their duty to give special attention to the subject of safety lamps’.

The Commissioners resolved, to test, practically, every form of safety lamp then in use, and to decide which, in their opinion, most nearly fulfilled the essential qualifications. For this purpose they invited makers, inventors, and users of safety lamps in the United Kingdom, Belgium, France, and Germany to send them lamps to be tested and reported on. In response, more than 250 lamps were sent in. Mr. Ellis Lever, realizing the importance of the task which the Commissioners had undertaken, offered a prize of 500 Pds Stlg for ‘the best safety lamp’, the tests to be conducted at Woolwich Arsenal by a specially selected committee which included several members of the Royal Commission.

The principle which guided the Royal Commission was that adopted by the Belgian and French Governments – viz., that the safest lamp was that which would most effectually withstand the influence of a strong current of explosive air.

Before the Commissioners, or the Woolwich Arsenal Committee, had concluded their tests, a French mining engineer (M. J. B. Marsuat) proved, by a series of elaborate experiments, that the principle was entirely wrong. He clearly demonstrated that, as there was no uniform velocity in the air-currents of a mine, a lamp constructed to burn safely in a strong current was a source of extreme danger when used in a stagnant atmosphere of explosive gas. His experiments proved that the gas entered the lamp, and remained there till the lamp was again brought in to a current sufficiently strong to force it through. The confined volume of gas then ignited and caused an explosion. This, M. Marsuat stated, ‘is an important key to certain accidents, hitherto ignored, assuredly very disquieting and which gives a key to certain accidents which have been difficult to explain’.

The Royal Commissioners frankly admitted their mistake. In their report (page 87) they stated: ‘The experiments conducted by M. Marsuat were so complete and so thoroughly established the truth of his observations that we thought it unnecessary to undertake a fresh investigation of the subject on an extended scale. We have, however, repeated a few of his experiments, and the results are in general accord with those obtained by him.’ Thus the Royal Commission and the Woolwich Arsenal Committee found no lamp then in use entirely fulfilled the essential qualifications they had established. The 500 Pds Stlg was not awarded.

The Royal Commissioners, however, finally decided in favor of four lamps, ‘in which the quality of safety, in a preeminent degree, is combined with simplicity of construction, and with illuminating power at least fully equal to that of the lamps hitherto in general use. These four lamps were: Gray’s Lamp, Evan Thomas No. 7, Marsuat, and Meuseler Bonneted. In our experiments the No. 7 has given, upon the whole, the best results.

They reported, however, that the use of the ‘Mueseler’ was attended with a certain amount of danger so ‘care must be taken to avoid a considerable inclination from the vertical direction, …. but with the Marsuat’ they stated, ‘there is no probability of the flame being extinguished under any circumstances attending ordinary use’. These statements were fully substantiated by the Woolwich Arsenal Committee. On the recommendation of the Royal Commissioners certain improvements were made in the ‘Marsuat’ Lamps, viz., in the locking of the lamp’s bottom and in fixing of the case. The illuminating power of the ‘Marsuat’ exceeds that of other kinds burning animal or vegetable oil.

An analysis of the Commissioners’ report shows that, though 250-300 lamps were tested, they had all, in a greater or a lesser degree, essential points of resemblance. They classified the oil burning lamps under six types, three English and three Belgian. The English types were the ‘Davy’, ‘Stephenson’ and ‘Clanny’; the Belgian types were the ‘Mueseler’, ‘Boty’ and ‘Eloin’. Of the ‘Eloin’ (patented in 1850), they reported ‘it is closely allied to the ‘Stephenson’ Lamp; of the original ‘Boty’ (adopted in 1 881 by the Belgian Government) they stated ‘it is a Clanny Lamp in general form’; and of the ‘Mueseler’ they reported ‘it is derived from the ‘Clanny”. Thus the safety lamps used so extensively on the Continent, at that time, were all adaptations of the three original English types.

Why It Matters

A thoroughly efficient safety lamp is not a mere mechanical contrivance for giving light in a coal mine. It is an instrument constructed in accordance with established laws of physical science. It ensures the burning of a protected flame in the presence of explosive gas, by regulating the necessary supply of atmospheric air, and by allowing the products of combustion to pass through without igniting the gaseous atmosphere. If the atmosphere is so heavily charged that noxious gas enters the lamp, its presence will be indicated by a change in the length and color of the flame, and (unless there are exceptional circumstances), the miner has sufficient warning to secure his safety.

The principles on which a thoroughly efficient safety lamp is constructed are practical, not theoretical. The component parts must all be in direct ratio. This ratio has been so accurately determined by practical tests, that any deviation from the established standards will adversely affect either the illuminating capacity of the lamp or its value as an indicator of danger. The reports of the Royal Commissioners on ‘Accidents in Mines’ (1886) and the Woolwich Arsenal Committee, show, however, that several inventors, and makers, who sent safety lamps for testing, or in competition, were either wholly ignorant of this fact and of the laws of physical science, or they did not regard them as of any importance.

The most flagrant deviation from established standards was in the case of the ‘Scotch Davy’, a lamp made in direct violation of the laws of physical science. Sir Humphrey Davy stated, as the result of protracted experiments, that ‘when a cylindrical gauze is used, it should not be more than 2 inches in diameter, for a larger cylinder the combustion of the firedamp renders the top inconveniently hot’. The ‘Scotch Davy’, however, was made from 2.9 in. to 3.3 in. in diameter. Davy restricted the height of his gauze to 7 inches; in the ‘Scotch Davy’ the height was 10 inches, exclusive of cap or top.