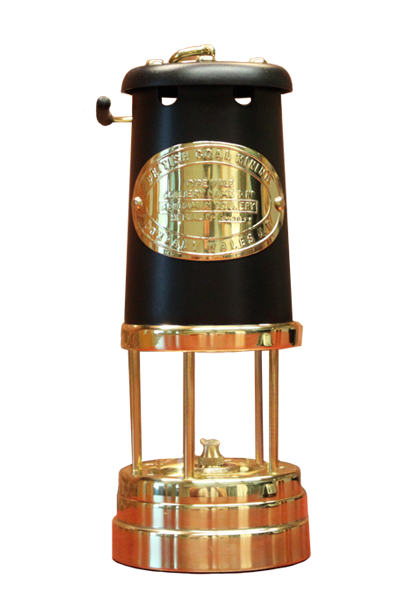

Kerosene Lamp Instructions

How to Fill your Kerosene Lamp

Recommended Fuel: Kerosene Based, Refined, High Quality Lamp Oil

Unscrew bottom fuel vessel. Unscrew knurled ring surrounding burner. Lift out burner and fill vessel with fuel. Replace burner and screwed knurled ring. Light wick and adjust flame to approximately 1/8″ by means of the Wick Pricker Pin. Screw fuel vessel to upper part of lamp and after allowing about one minute for the lamp to achieve air circulation, the flame can be raised to the required height. A flame height of 1/2″ is recommended.

First apply a light smearing of metal cleaning agent (ie. Brasso, Wenol) and using a dry, soft, clean cloth, rub off briskly to achieve a bright polished finish.

It is important that the wick be cut level with the burner tube, and that the carbon deposit be cleaned off regularly, to ensure a bright light. To dismantle, first unscrew the fuel vessel to expose the brass ring supporting the lamp glass. The ring is slotted and, by means of a suitable forked tool, (a flat headed screw driver can work) it can be unscrewed to release the inner fittings. Care should be taken to see that all parts are replaced in the correct order.

Please note: Do Not Overfill the Fuel Vessel. We suggest the fuel vessel be ¾ full.

Caution: Do not use any type of spirit or alcohol based fuel.

Working Instructions for Kerosene Lamp

Recommended Fuel: refined kerosene ( lamp oil)

The lamp should always be handed to the workmen with a small flame and as the lamp heats up, the flame increases automatically, and will burn throughout the remainder of the shift. the height of the flame when finally adjusted in normal conditions should be approximately 1/2″. it is important that the wick should be cut level with the burner tube and the carbon deposit cleaned off after every shift to ensure a bright light.

Please note: do not use any type of spirit fuel

The internal gauze’s are treated with a coating of light preserving oil and therefore when first lit this coating will burn off producing a little smoke temporarily.